Efficient Electromagnetic Shields in the GHz and Sub-THz Frequency Bands

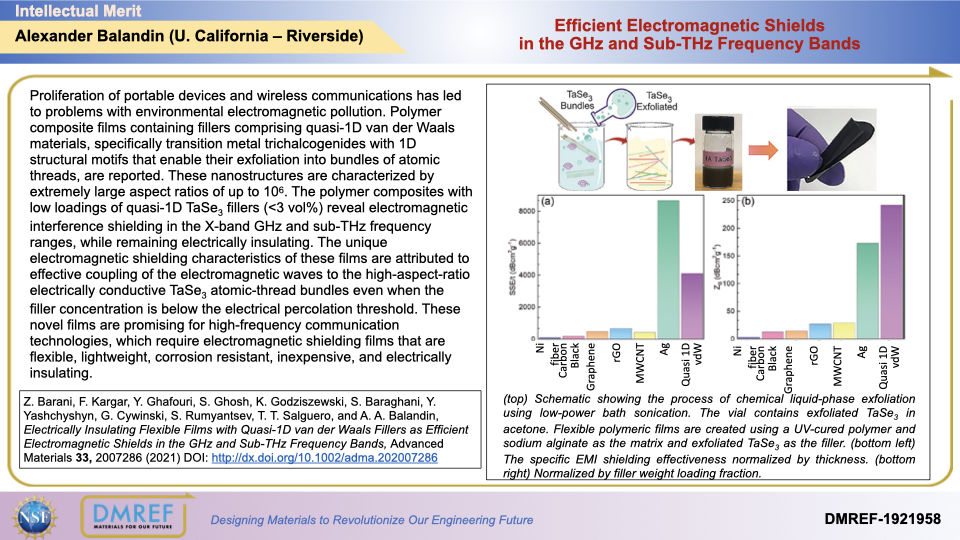

Proliferation of portable devices and wireless communications has led to problems with environmental electromagnetic pollution. Polymer composite films containing fillers comprising quasi-1D van der Waals materials, specifically transition metal trichalcogenides with 1D structural motifs that enable their exfoliation into bundles of atomic threads, are reported. These nanostructures are characterized by extremely large aspect ratios of up to 106.

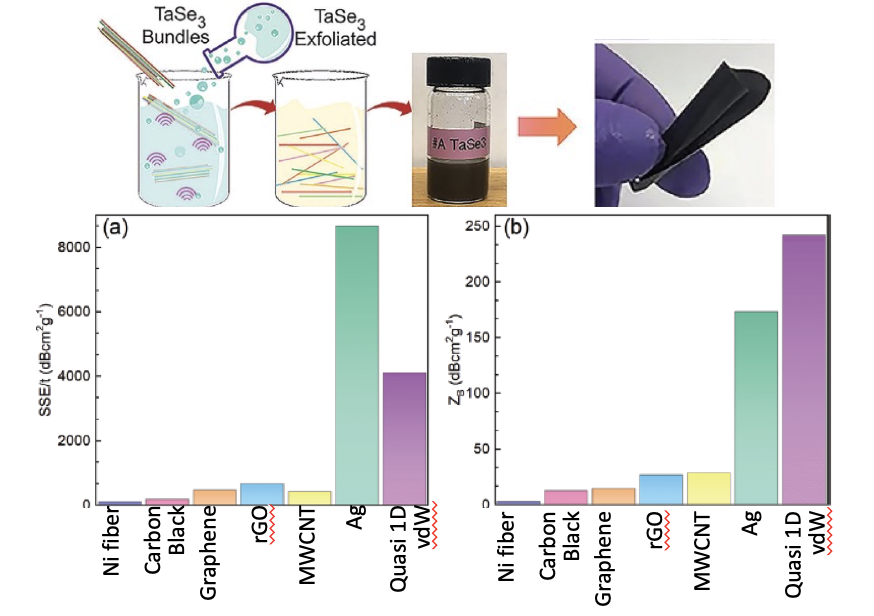

The polymer composites with low loadings of quasi-1D TaSe3 fillers (<3 vol%) reveal electromagnetic interference shielding in the X-band GHz and sub-THz frequency ranges, while remaining electrically insulating. The unique electromagnetic shielding characteristics of these films are attributed to effective coupling of the electromagnetic waves to the high-aspect-ratio electrically conductive TaSe3 atomic-thread bundles even when the filler concentration is below the electrical percolation threshold.

These novel films are promising for high-frequency communication technologies, which require electromagnetic shielding films that are flexible, lightweight, corrosion resistant, inexpensive, and electrically insulating.