Storing Information with Magnetic Encoding

Biological materials gain complexity from the programmable nature of their parts. To synthetically manufacture materials with comparable complexity, building blocks need to be created with low crosstalk when they only bind to their desired partners. Canonically, these building blocks are made using DNA strands or proteins to achieve specificity.

Here Harvard and Cornell's researchers propose a new materials platform, Magnetic Handshake Materials, with programmable interactions using patterns of magnetic dipoles. This is a complete synthetic platform, enabled by magnetic printing technology, which is easier to both control and model in the laboratory.

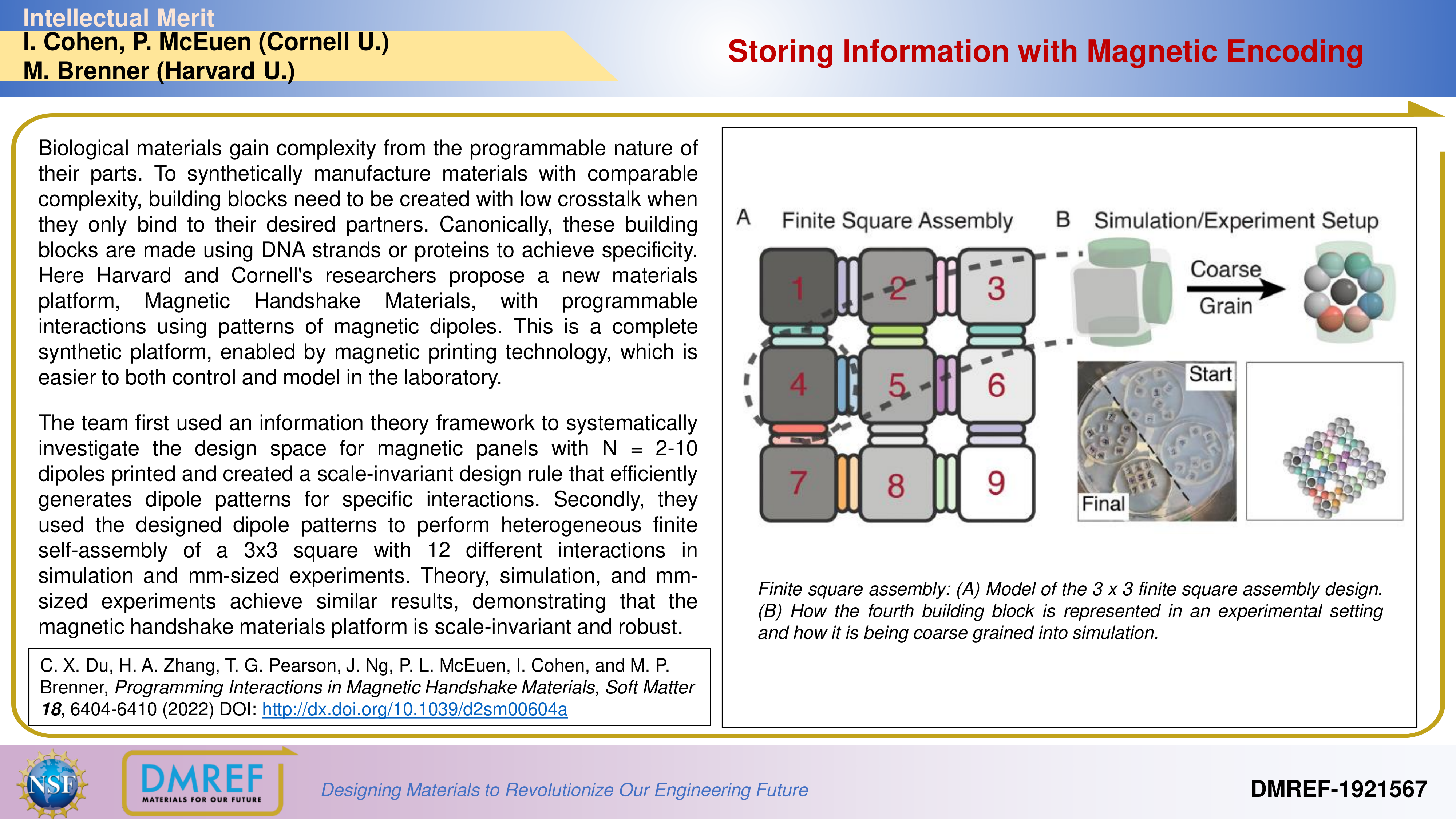

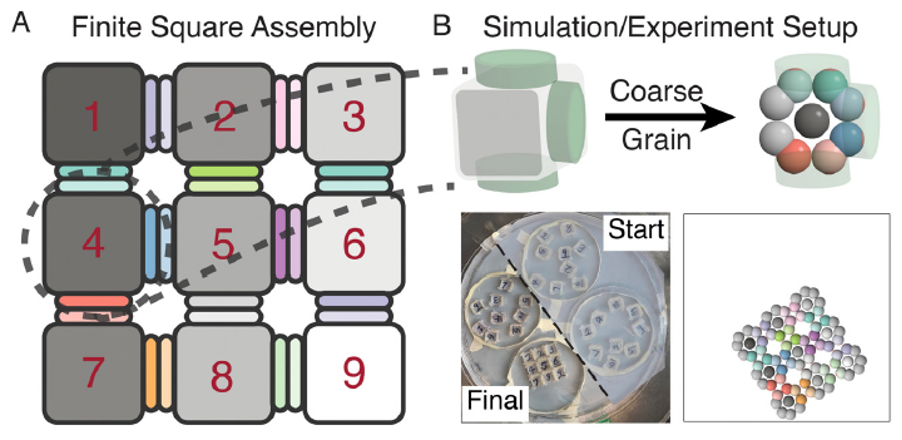

The team first used an information theory framework to systematically investigate the design space for magnetic panels with N = 2-10 dipoles printed and created a scale-invariant design rule that efficiently generates dipole patterns for specific interactions. Secondly, they used the designed dipole patterns to perform heterogeneous finite self-assembly of a 3x3 square with 12 different interactions in simulation and mm-sized experiments. Theory, simulation, and mm-sized experiments achieve similar results, demonstrating that the magnetic handshake materials platform is scale-invariant and robust.