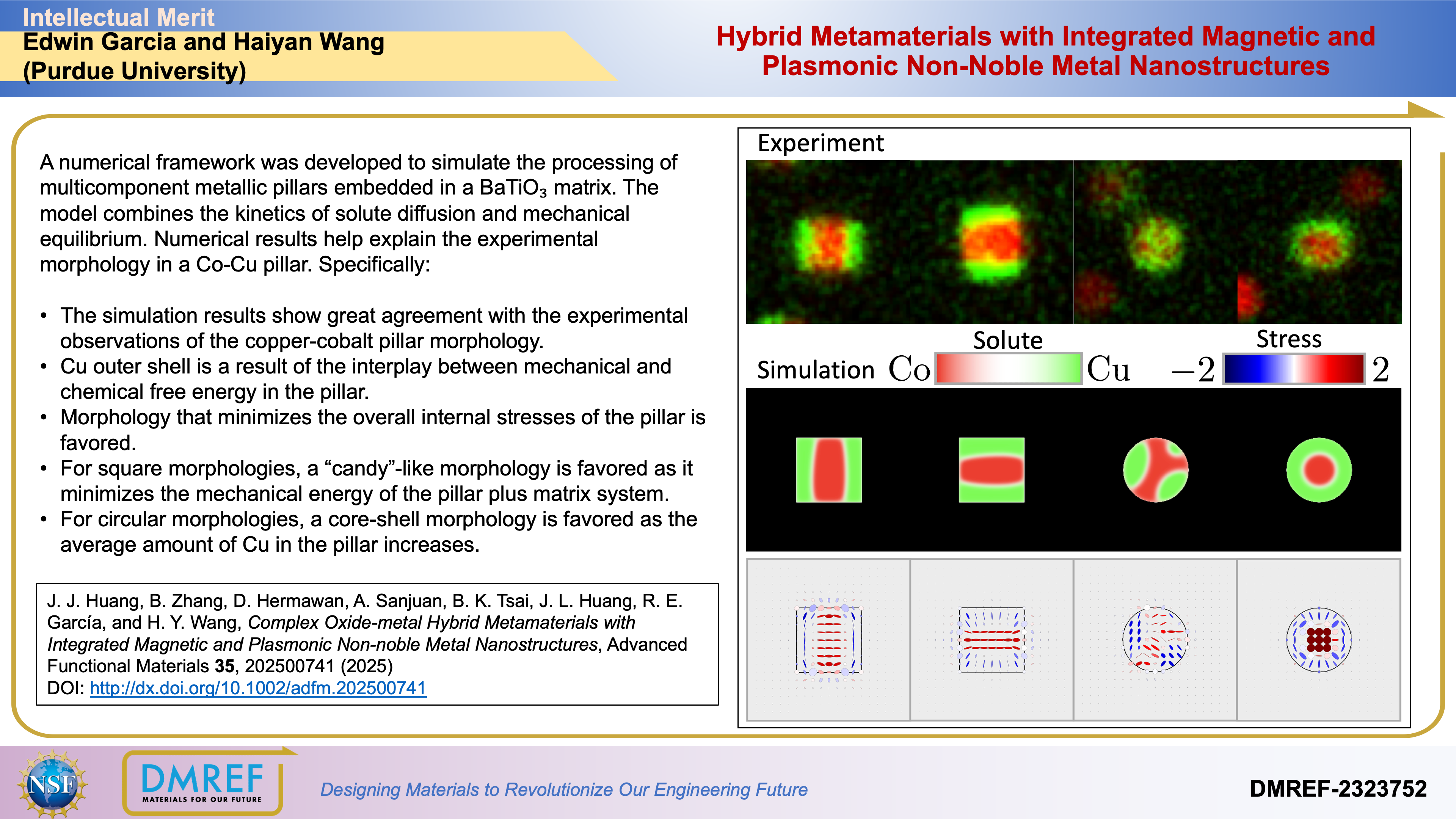

Hybrid Metamaterials with Integrated Magnetic and Plasmonic Non-Noble Metal Nanostructures

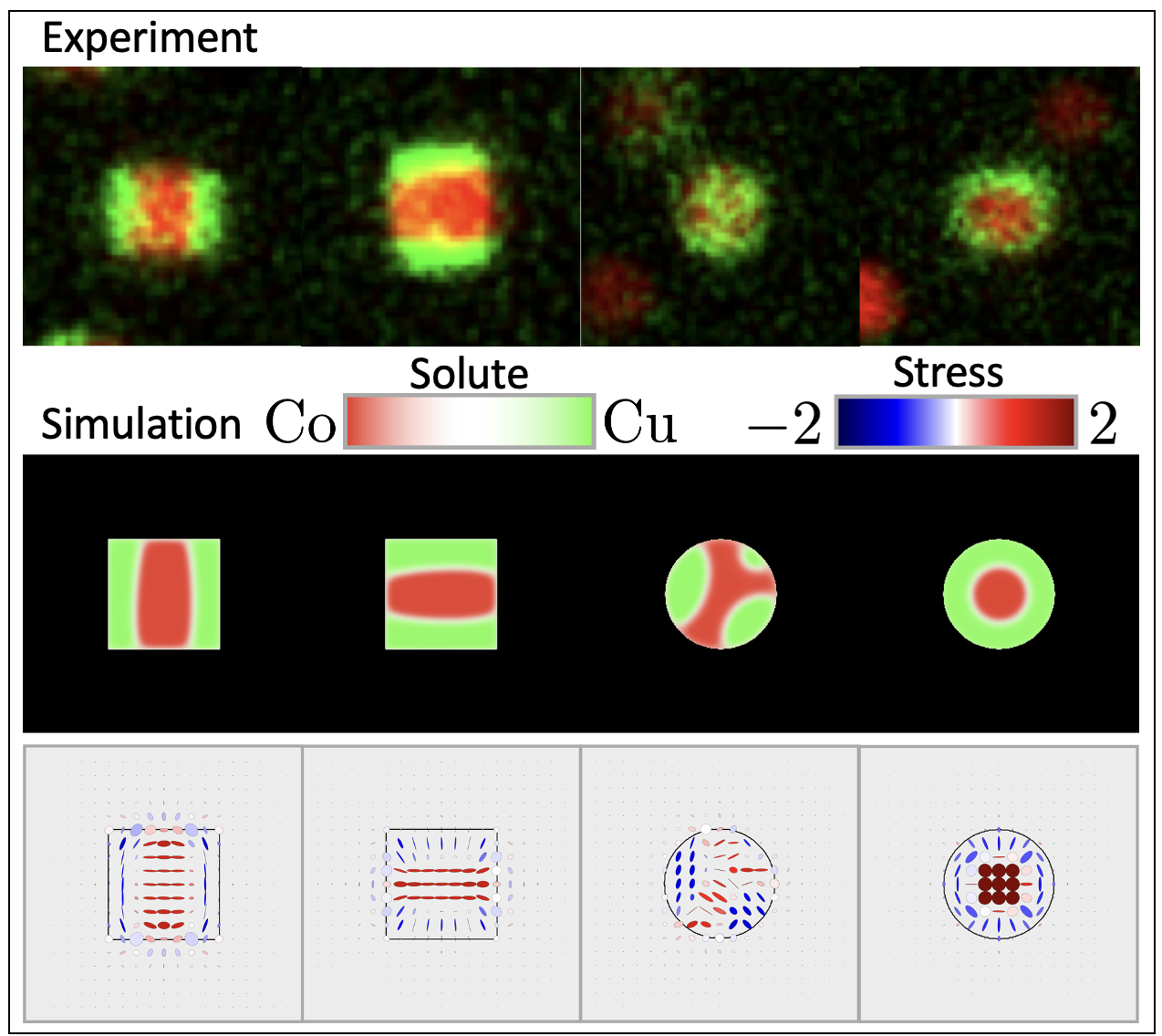

A numerical framework was developed to simulate the processing of multicomponent metallic pillars embedded in a BaTiO₃ matrix. The model combines the kinetics of solute diffusion and mechanical equilibrium. Numerical results help explain the experimental morphology in a Co-Cu pillar. Specifically:

The simulation results show great agreement with the experimental observations of the copper-cobalt pillar morphology.

Cu outer shell is a result of the interplay between mechanical and chemical free energy in the pillar.

Morphology that minimizes the overall internal stresses of the pillar is favored.

For square morphologies, a “candy”-like morphology is favored as it minimizes the mechanical energy of the pillar plus matrix system.

For circular morphologies, a core-shell morphology is favored as the average amount of Cu in the pillar increases.