Rapid Development of Metal Additive Manufacturing Using Machine Learning and High-throughput Testing

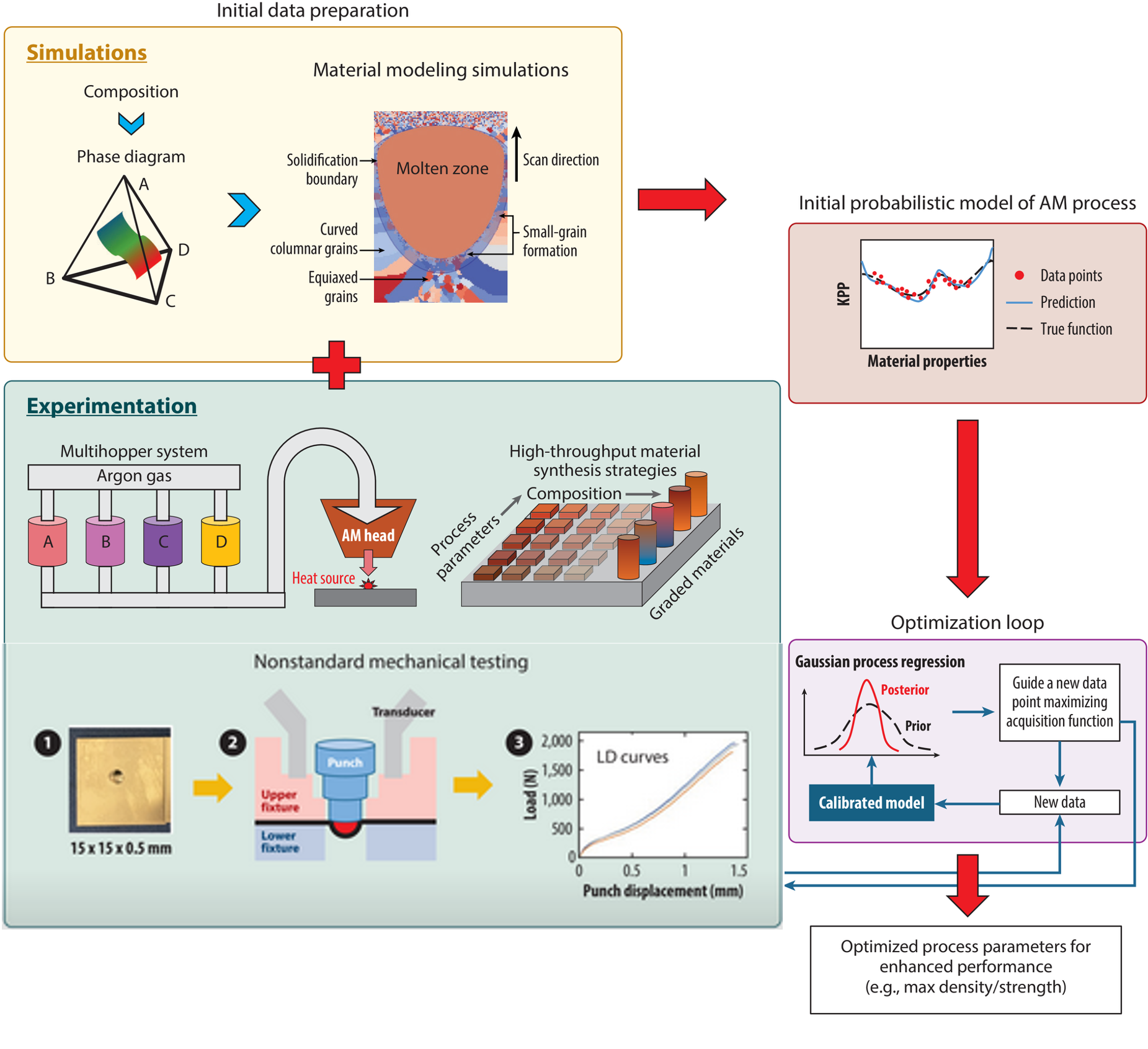

Metal additive manufacturing (AM) holds immense potential for developing advanced structural alloys. However, the complex, heterogeneous nature of AM-produced materials presents significant challenges to traditional material characterization and optimization methods. The integration of artificial intelligence (AI) and machine learning (ML) was explored with high-throughput material characterization protocols to rapidly establish the process–structure–property (PSP) relationships critically needed to dramatically accelerate the development of metal AM processes. Combinatorial high-throughput evaluations, including rapid material synthesis and non- standard high-throughput testing protocols, such as spherical indentation and small punch tests, are discussed for their capability to rapidly assess mechanical properties and establish PSP linkages. Furthermore, the role of AI and ML was examined in optimizing AM processes, particularly through Bayesian optimization, which offers new avenues for efficient exploration of high-dimensional design spaces. A future is envisioned where AI- and ML-driven, autonomous AM development cycles significantly enhance material and process optimization.