Computational Design of Mechanically Coupled Axle-rotor Protein Assemblies

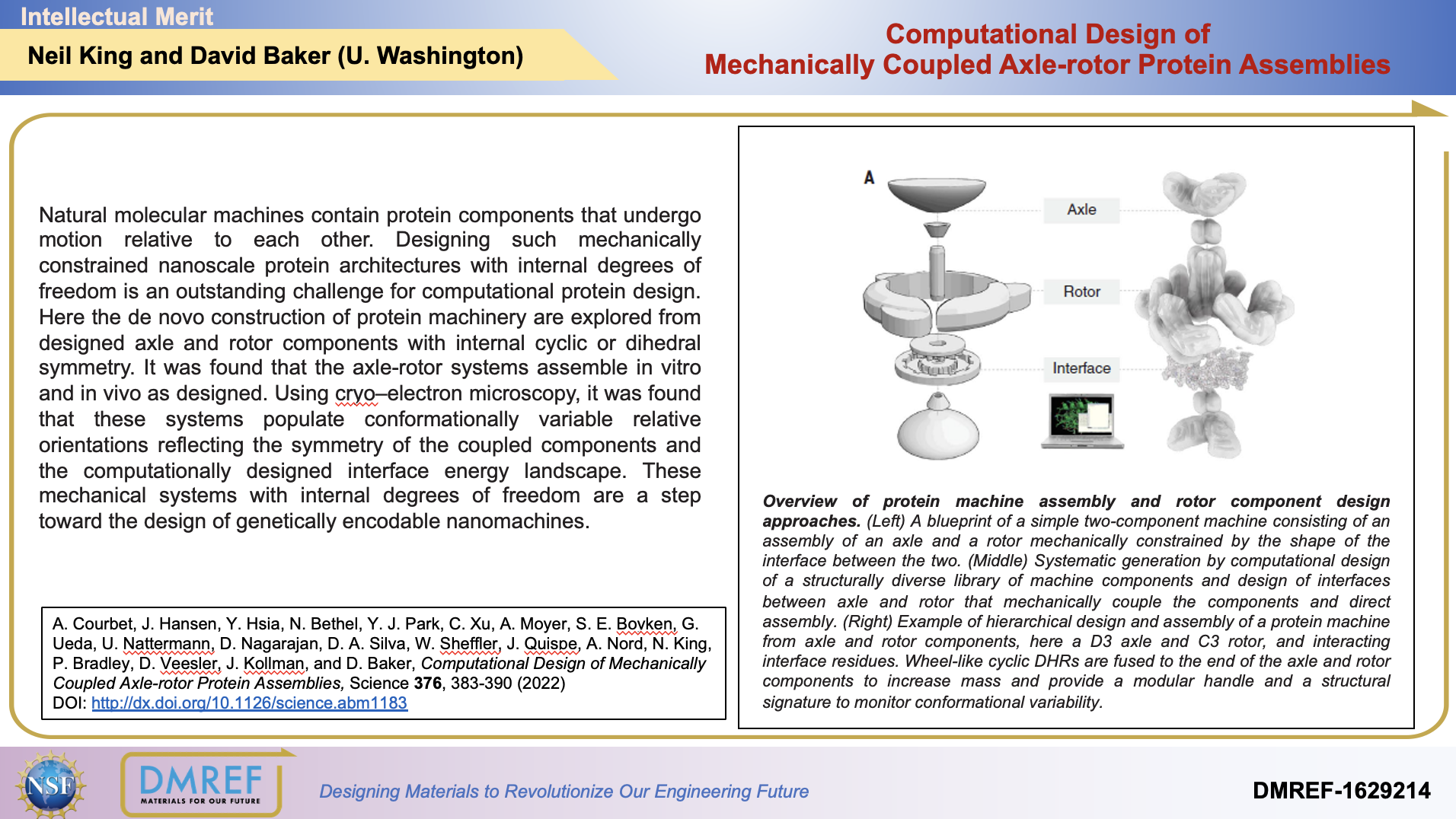

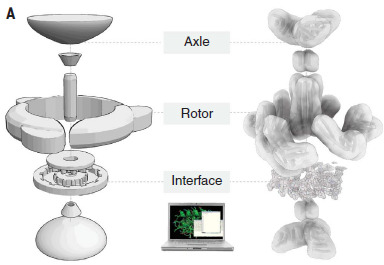

Natural molecular machines contain protein components that undergo motion relative to each other. Designing such mechanically constrained nanoscale protein architectures with internal degrees of freedom is an outstanding challenge for computational protein design. Here the de novo construction of protein machinery are explored from designed axle and rotor components with internal cyclic or dihedral symmetry. It was found that the axle-rotor systems assemble in vitro and in vivo as designed. Using cryo–electron microscopy, it was found that these systems populate conformationally variable relative orientations reflecting the symmetry of the coupled components and the computationally designed interface energy landscape. These mechanical systems with internal degrees of freedom are a step toward the design of genetically encodable nanomachines.