Grain Boundary Velocity Distributions

Apr 1, 2019

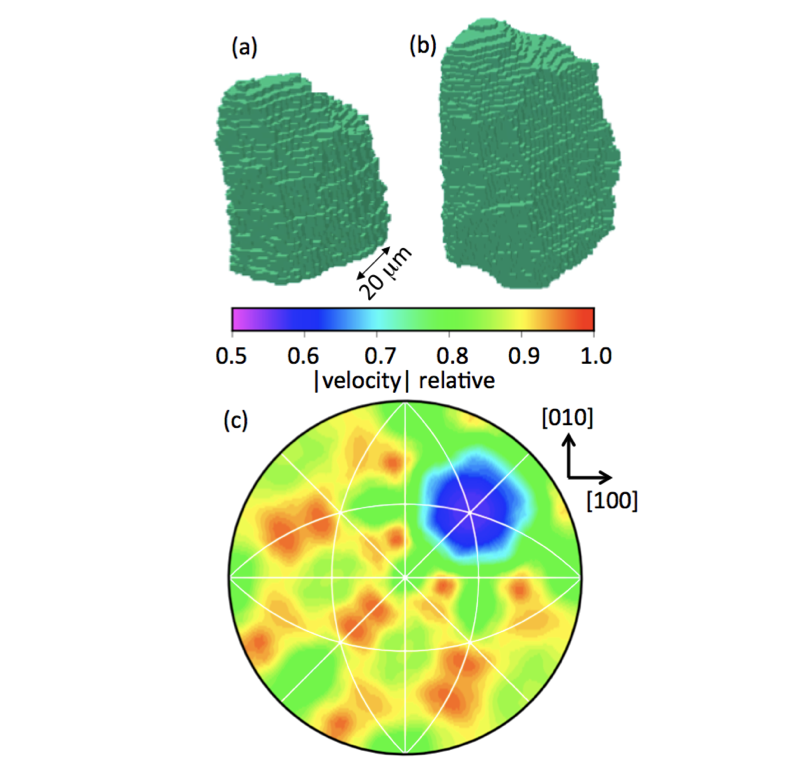

Polycrystalline metals and ceramics are opaque to most forms of radiation. Because of this, it has not been possible to observe the motion of grain boundaries within a polycrystalline network. Using high energy x-ray diffraction microscopy, we have observed how crystals embedded in a polycrystalline network change shape during annealing. For example, the crystal in (a) grew in size after annealing (b). By tracking the motion of thousands of boundaries, we were able to classify the grain boundary velocity as a function of grain boundary crystallographic orientation (c). Surprisingly, the velocity is a strong function of crystallographic orientation.

Microstructure evolution during the processing of metals and ceramics is an important but poorly understood process that influences a variety of properties. These findings will make it possible for simulations to better predict processing conditions that lead to materials with ideal properties

Figure caption: (a) single crystal grain within a Ni polycrystal. (b) after 2.5 h annealing at 800 °C. (c) The distribution of grain boundary velocities as a function of boundary orientation, for those boundaries with a 60° disorientation about the [111] axis.