Data Mining for Parameters Affecting Polymorph Selection

The macroscopic properties of molecular materials can be drastically influenced by their solid-state packing arrangements, of which there can be many (e.g., polymorphism). Strategies to controllably and predictively access select polymorphs are desired, but predicting the conditions necessary to access a given polymorph is challenging with the current state of the art.

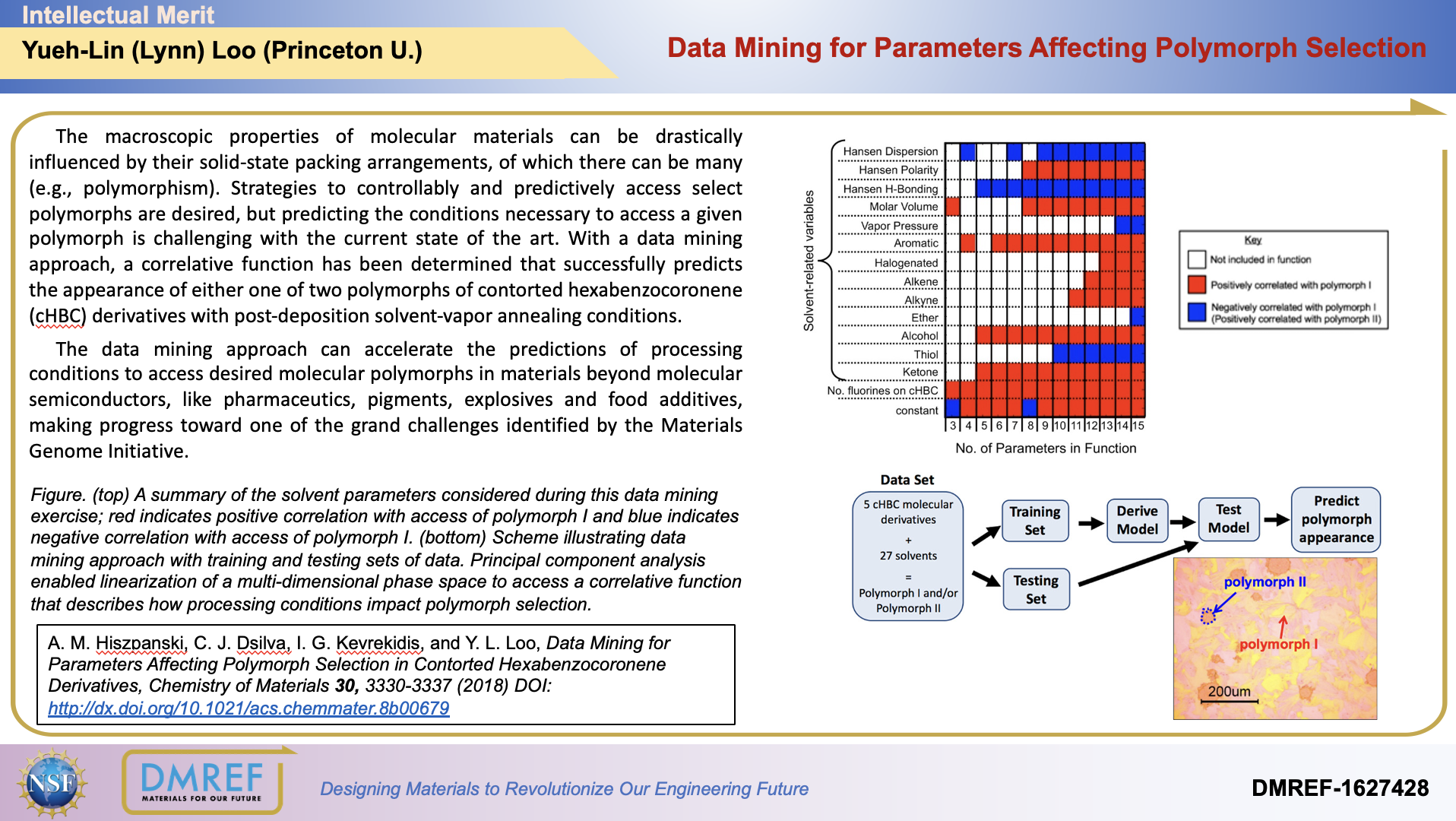

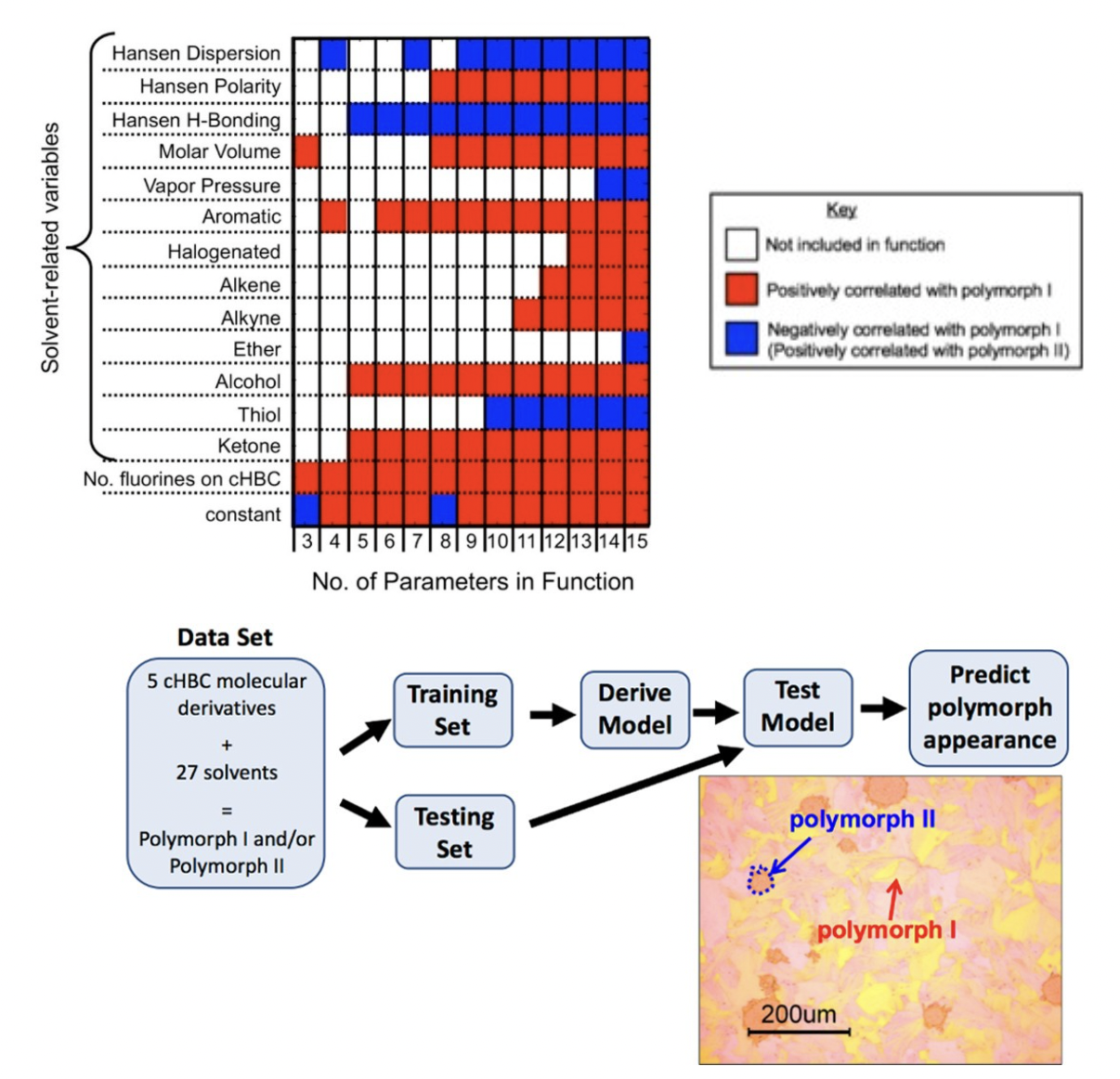

With a data mining approach, a correlative function has been determined that successfully predicts the appearance of either one of two polymorphs of contorted hexabenzocoronene (cHBC) derivatives with post-deposition solvent-vapor annealing conditions.

The data mining approach can accelerate the predictions of processing conditions to access desired molecular polymorphs in materials beyond molecular semiconductors, like pharmaceutics, pigments, explosives and food additives, making progress toward one of the grand challenges identified by the Materials Genome Initiative.